In Fill Panels Things To Know Before You Get This

Table of ContentsEverything about In Fill PanelsNot known Facts About In Fill PanelsIn Fill Panels for Dummies

Infill panels are utilized in between articles of guard barrier to produce the obstacle for loss protection on stairs, verandas, as well as pathways. Perforated infill panels, woven wire panels, or laser cut panels offer intriguing means to fill up the area in between articles. in fill panels.

Infill panels are often set up on building exteriors as a drape wall, a rainscreen, or assistance for various other cladding product. They may be solid, or more ornamental as in perforated panels or a laser cut layout.

Steel infill panels offer a fantastic means to add safety and security to areas that require that. They are reasonably lightweight as well as can be included or eliminated as desired. They let light as well as air with as well as can be developed with creativity to improve the area and the look of the building.

Not known Factual Statements About In Fill Panels

There are numerous methods to cover a ceiling to hide the joists or trusses and also utilities that run in ceilings. in fill panels. One means is with making use of steel infill panels, specifically when an extra commercial appearance is preferred. A perforated, or a woven cord pattern works well for ceiling panels.

Bus shelters, Park and Trip waiting locations, Band shells, Parks, Zoos, Playgrounds, Residential housing are all areas where infill panels are used.

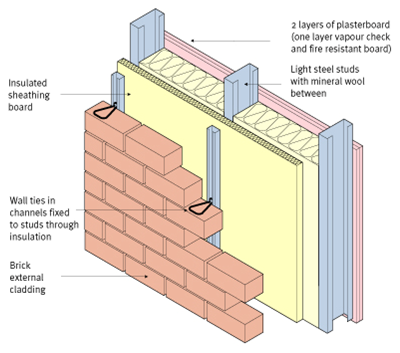

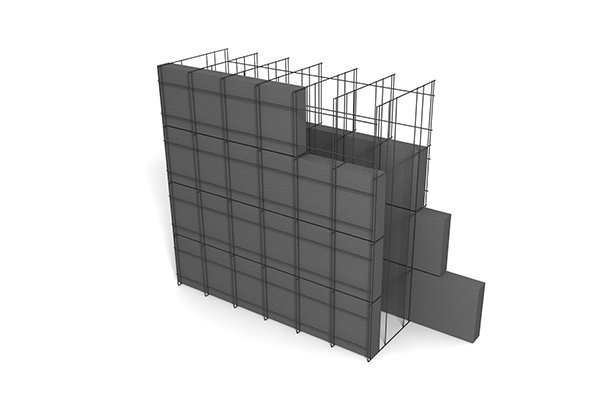

are a type of cladding built between the structural participants of a structure. The structural framework provides support for the cladding system, and the cladding offers separation of the interior and also exterior environments. Infill walling is different to various other kinds of cladding panel because it is fixed between framing participants instead of being affixed to the beyond the structure. are not taken into consideration to be lots bearing, although they are required to resist wind loads put on the faade, as well as sustaining their very own weight. Various other useful demands for consist of:.

See This Report about In Fill Panels

Typically, made use of brick/masonry or lumber; nevertheless, these are even more time consuming than modern-day choices as well as have been my review here largely replaced by lightweight steel C- sections that span in between floors as well as around openings. These can be constructed from clay blocks or concrete blocks, in a strong or cavity form. The very same principles of solid as well as tooth cavity wall surface building put on. They can be linked to columns using wall surface ties cast at 300 mm centres, or located in anchor ports. These are typically huge precast concrete panels that are the height of one storey as well as of a size dictated by the spacing of the structure. in fill panels. Panels that are important might be clad in other products, most generally rock. The maximum panel dimension is generally limited by the transportation factors to considerand also crane training capacity. sections are cut to size commonly 90 as well as 140 mm depth to span 2. 4- 3. 6 m between floorings and also put at 400 or 600 mm spacings. The downside of making use of lumber in place of steel is that it has much less stamina and also can not be utilized in tall areas or walls with large openings for doors or windows. @ & & h3 @ [edit] Lightweight steel infill panels @&&/h3@ @&&h1@ [modify] Learn even more @&&/h1@ @ & & h3 @ Ask Our Professionals: What Are Infill Panels? @&&/h3@ Before you decide whether infill panels are ideal for your certain building design or other application, you need to have a firm grasp on what they in fact are. Infill panels, otherwise called infill walls, are non-load-bearing. They are set up

between floors on the primary architectural framework of a building to sustain the framework's cladding system. These panels are also made use of internally to create dividing wall surfaces that boost acoustic read here insulation as well as fire resistance within a structure. Originally, infill panels were produced mostly from masonry, concrete and also various other hefty products. Today's architectural designs, nevertheless, frequently use light metal infill panels to produce a high-grade as well as aesthetically pleasing framework. @&&h3@ Kinds of Metal Infill Panels @&&/h3@ Once you have actually decided that these panels are proper for your building style, it's time to take into consideration choices: Produced with a process of synchronised stretching as well as slitting, this steel is solid, light-weight and also much more cost-effective than lots of other made metals. It has diamond-shaped openings over its surface area, offering it a special look. Since the product in this procedure can be expanded up to 10 times the dimension it started at, the end product evaluates concerning a fifth what it did yet still keeps its basic stability as well as strength. These panels give premium strength for a building facade or other application. Choices for this sort of infill consist of welded steel, press-locked and also riveted bar grating, every one of which join bars with each other to develop a durable last item that can enhance safety and also provide an enticing building look. @&&h3@ Marco Specialized Steel as Your Infill Panel Provider @&&/h3@ @&&h3@ Display Infill Standard Links @&&/h3@ Accessory techniques showed are common offerings for Aria60LG, Aria80LG, as well as Aria100LG. @&&h3@ Gateway Alternatives @&&/h3@ Making use of try this website Aria items as the focal point of the style, gates are customized made and also produced to satisfy dimensional as well as equipment needs. @&&h3@ Sunshade Requirement Connections @&&/h3@ Criterion links for each and every product type are illustrated below.